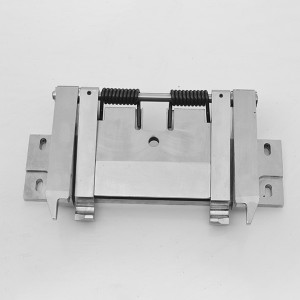

Stamping ndondomeko

Kupondaponda (komwe kumadziwikanso kuti kukanikiza) ndi njira yoyika chitsulo chathyathyathya mopanda kanthu kapena ngati koyilo mu makina osindikizira pomwe chida ndi pamwamba pake zimapanga chitsulocho kukhala ukonde.Kupondaponda kumaphatikizapo njira zosiyanasiyana zopangira zitsulo, monga kukhomera pogwiritsa ntchito makina osindikizira kapena kusindikiza, kubisa kanthu, kusindikiza, kupindika, kupindika, ndi kupanga ndalama.Izi zitha kukhala ntchito imodzi yokha pomwe kugunda kulikonse kwa makina osindikizira kumatulutsa mawonekedwe omwe amafunidwa pagawo lachitsulo, kapena kumatha kuchitika motsatizana.Njirayi nthawi zambiri imachitika pazitsulo zachitsulo, koma ingagwiritsidwenso ntchito pazinthu zina, monga polystyrene.Progressive dies nthawi zambiri amadyetsedwa kuchokera ku koyilo yachitsulo, koyilo ya koyilo kuti amasulire koyilo kupita ku chowongola kuti ayendetse koyiloyo kenako kulowa mu feeder yomwe imapititsa zinthuzo ku makina osindikizira ndikufa pautali wokonzedweratu.Kutengera ndi zovuta zina, kuchuluka kwa masiteshoni mu kufa kumatha kuzindikirika.

Kupondaponda kumachitika pa pepala lozizira lachitsulo.Onani Forging pakupanga zitsulo zotentha.

Chitsulo chosapanga dzimbiri: SS304, SS304L, SS316, SS316L, SS303, SS630

Chitsulo cha carbon: 35CrMo, 42CrMo, ST-52, Ck45, chitsulo cha alloy;ST-37, S235JR, C20, C45, 1213, 12L14 chitsulo cha carbon;

Aloyi yamkuwa: C36000, C27400, C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2

Aluminiyamu aloyi: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A.

1. Kupinda - zinthuzo ndi zopunduka kapena kupindika molunjika.

2. Flanging - zinthuzo zimapindika motsatira mzere wokhotakhota.

3. Kujambula - zinthuzo zimatambasulidwa kukhala kupsinjika kozama.Amagwiritsidwa ntchito makamaka powonjezera mapangidwe okongoletsera.

4. Chopanda kanthu - chidutswa chimadulidwa kuchokera pa pepala la zinthuzo, nthawi zambiri kuti apange chopanda kanthu kuti apitirize kukonza.

5. Coining - chitsanzo amapanikizidwa kapena kufinyidwa mu zinthu.Kale ankapanga makobidi.

6. Kujambula - malo opanda kanthu amatambasulidwa kukhala mawonekedwe ena kudzera mumayendedwe oyendetsedwa bwino.

7. Kutambasula - pamwamba pa malo opanda kanthu kumawonjezeka ndi kupanikizika, popanda kuyenda kwamkati kwa m'mphepete mwake.Nthawi zambiri amagwiritsidwa ntchito popanga ziwalo zosalala za thupi.

8. Kusita - zinthuzo zimafinyidwa ndikuchepetsedwa mu makulidwe pakhoma loyima.Amagwiritsidwa ntchito ngati zitini zakumwa komanso ma cartridge amfuti.

9. Kuchepetsa / Kukhota - kumagwiritsidwa ntchito kuchepetsa pang'onopang'ono m'mimba mwake kumapeto kwa chotengera kapena chubu.

10. Kupiringa - kupundutsa zinthu kukhala tubular mbiri.Zitseko za zitseko ndi chitsanzo chofala.

11. Kumangirira - kupindika m'mphepete kuti muwonjezere makulidwe.Mphepete mwa zitseko zamagalimoto nthawi zambiri amatsekeredwa.

Kuboola ndi kudula kungathenso kuchitidwa mu makina osindikizira.Progressive stamping ndi kuphatikiza kwa njira zomwe zili pamwambazi zomwe zimachitika ndi ma dies motsatana momwe mzere wazinthu umadutsa sitepe imodzi.

Zigawo zosindikizidwa zakuda

Stamping ndondomeko

Zitsulo ozizira kupondaponda mbali