CNC mphero ndondomeko

Kuwongolera manambala (komanso kuwongolera manambala apakompyuta, komwe kumadziwikanso kuti CNC) ndiko kuwongolera pazida zopangira makina (monga zobowolera, ma lathe, mphero ndi osindikiza a 3D) pogwiritsa ntchito kompyuta.Makina a CNC amakonza kachidutswa (chitsulo, pulasitiki, matabwa, ceramic, kapena kompositi) kuti akwaniritse zofunikira potsatira malangizo omwe ali ndi ndondomeko komanso popanda wogwiritsa ntchito pamanja kuwongolera makinawo.

Makina a CNC ndi chida chowongolera choyendetsedwa ndi injini ndipo nthawi zambiri ndi nsanja yosunthika, yomwe imayendetsedwa ndi kompyuta, molingana ndi malangizo olowera.Malangizo amaperekedwa ku makina a CNC mu mawonekedwe a pulogalamu yotsatizana ya malangizo owongolera makina monga G-code ndi M-code, kenako amaphedwa.Pulogalamuyi imatha kulembedwa ndi munthu kapena, nthawi zambiri, kupangidwa ndi pulogalamu yamapulogalamu opangidwa ndi makompyuta (CAD) ndi/kapena mapulogalamu othandizira pakompyuta (CAM).Pankhani ya osindikiza a 3D, gawo loti lisindikizidwe ndi "lodulidwa", malangizo (kapena pulogalamu) asanapangidwe.Osindikiza a 3D amagwiritsanso ntchito G-Code.

CNC ndikusintha kwakukulu pamakina osagwiritsa ntchito makompyuta omwe amayenera kuyendetsedwa pamanja (monga kugwiritsa ntchito zida monga mawilo am'manja kapena ma levers) kapena kuyendetsedwa mwamakina ndi maupangiri opangidwa kale (makamera).M'makina amakono a CNC, mapangidwe a gawo lamakina ndi pulogalamu yake yopangira ndizodziwikiratu.Makulidwe amakina a gawolo amatanthauzidwa pogwiritsa ntchito mapulogalamu a CAD kenako amamasuliridwa kukhala malangizo opangira makina opangira makompyuta (CAM).Zotsatira zake zimasinthidwa (ndi pulogalamu ya "post processor") kukhala malamulo ofunikira kuti makina enaake apange chigawocho kenako ndikulowetsedwa mu makina a CNC.

Popeza chigawo china chilichonse chingafunike kugwiritsa ntchito zipangizo zosiyanasiyana - kubowola, macheka, ndi zina zotero - makina amakono nthawi zambiri amaphatikiza zida zambiri mu "selo" imodzi.M'makhazikitsidwe ena, makina angapo osiyanasiyana amagwiritsidwa ntchito ndi woyang'anira wakunja komanso oyendetsa anthu kapena robotic omwe amasuntha gawolo kuchokera pamakina kupita ku makina.Mulimonse momwe zingakhalire, mndandanda wa masitepe ofunikira kuti mupange gawo lililonse umakhala wokhazikika kwambiri ndipo umapanga gawo lomwe limagwirizana kwambiri ndi zojambula zoyambirira za CAD.

Kudula ndi njira yodulira yomwe imagwiritsa ntchito chodulira mphero kuchotsa zinthu pamwamba pa ntchito.Chodulira mphero ndi chida chodulira mozungulira, nthawi zambiri chimakhala ndi malo odulira angapo.Mosiyana ndi kubowola, kumene chida patsogolo pa kasinthasintha ake olamulira, wodula mu mphero zambiri anasuntha perpendicular olamulira ake kuti kudula kumachitika pa circumference wa wodulayo.Pamene wodula mphero akulowa mu ntchito, zitsulo zodula (zitoliro kapena mano) za chidacho zimadulidwa mobwerezabwereza ndikutuluka kuchokera kuzinthuzo, kumeta tchipisi (swarf) kuchokera pachidutswa chilichonse.Ntchito yodula ndikumeta ubweya;Zinthuzo zimakankhidwa kuchokera pachinthucho m'timagulu ting'onoting'ono tomwe timalumikizana mokulirapo kapena pang'ono (kutengera zinthuzo) kuti apange tchipisi.Izi zimapangitsa kudula kwachitsulo kukhala kosiyana (mu makina ake) kuchokera kuzitsulo zofewa ndi tsamba.

Mpheroyo imachotsa zinthu podula mabala ang'onoang'ono.Izi zimatheka pogwiritsa ntchito chodulira chokhala ndi mano ambiri, kupota chodulacho pa liwiro lalikulu, kapena kupititsa patsogolo zinthuzo kudzera mwa choduliracho pang’onopang’ono;nthawi zambiri zimakhala zophatikizika mwa njira zitatuzi.[2]Kuthamanga ndi zakudya zomwe zimagwiritsidwa ntchito zimasiyanasiyana kuti zigwirizane ndi mitundu yosiyanasiyana.Liwiro limene chidutswacho chimadutsa pa choduliracho chimatchedwa mlingo wa chakudya, kapena chakudya chokha;kaŵirikaŵiri amapimidwa monga mtunda panthaŵi ( mainchesi pa mphindi [mu/mphindi kapena ipm] kapena mamilimita pa mphindi [mm/min]), ngakhale kuti mtunda pa kuzungulira kapena pa dzino locheka nawonso nthaŵi zina amagwiritsidwa ntchito.

Pali mitundu iwiri ikuluikulu ya mphero:

1.Mu mphero ya nkhope, kudula kumachitika makamaka kumapeto kwa mphero.Kupukuta kumaso kumagwiritsidwa ntchito kudula malo athyathyathya (nkhope) kuti agwiritse ntchito, kapena kudula mazenera apansi.

2.Mu mphero zotumphukira, ntchito yodula imachitika makamaka mozungulira chodulira, kotero kuti gawo la mtanda la milled limatha kulandira mawonekedwe a wodulayo.Pamenepa masamba a chodulira amatha kuwoneka ngati akutulutsa zinthu kuchokera pachinthucho.Mphero zotumphukira ndizoyenera kudula mipata yakuya, ulusi, ndi mano a zida.

| CNC makina | Kufotokozera |

| Chigayo | Amamasulira mapulogalamu okhala ndi manambala ndi zilembo kuti asunthire spindle (kapena chogwirira ntchito) kupita kumalo osiyanasiyana ndi kuya kwake.Ambiri amagwiritsa ntchito G-code.Ntchito zikuphatikizapo: mphero kumaso, mphero mapewa, kugogoda, kubowola ndipo ena amapereka kutembenuka.Masiku ano, mphero za CNC zimatha kukhala ndi nkhwangwa zitatu mpaka 6.Ambiri CNC mphero amafuna kuyika workpiece pa kapena mwa iwo ndipo ayenera kukhala wamkulu ngati workpiece, koma makina atsopano 3-olamulira akupangidwa kuti ndi ang'onoang'ono kwambiri. |

| Lathe | Amadula workpieces pamene iwo amasinthasintha.Amadula mwachangu, molondola, pogwiritsa ntchito zida zolozera komanso kubowola.Zothandiza pamapulogalamu ovuta omwe adapangidwa kuti apange magawo omwe sangatheke kupanga pamalawi apamanja.Zofananira zowongolera ku mphero za CNC ndipo zimatha kuwerenga G-code.Nthawi zambiri amakhala ndi nkhwangwa ziwiri (X ndi Z), koma mitundu yatsopano imakhala ndi nkhwangwa zambiri, zomwe zimalola kuti ntchito zapamwamba zitheke. |

| Wodula plasma | Zimaphatikizapo kudula zinthu pogwiritsa ntchito tochi ya plasma.Amagwiritsidwa ntchito podula zitsulo ndi zitsulo zina, koma angagwiritsidwe ntchito pazinthu zosiyanasiyana.Pochita izi, gasi (monga mpweya woponderezedwa) amawombedwa ndi liwiro lalikulu kuchokera pamphuno;panthawi imodzimodziyo, arc yamagetsi imapangidwa kupyolera mu mpweya umenewo kuchokera pamphuno kupita pamwamba ndikudulidwa, kutembenuza mpweya wina kukhala plasma.Madzi a m'magazi ndi otentha mokwanira kusungunula zinthu zomwe zadulidwazo ndipo zimayenda mofulumira kwambiri kuti ziwumbe zitsulo zosungunuka kuchoka pa kudula. |

| Makina otulutsa magetsi | (EDM), yomwe imadziwikanso kuti spark machining, spark eroding, kuwotcha, kufa, kapena kukokoloka kwa waya, ndi njira yopangira momwe mawonekedwe omwe amafunidwira amapezedwa pogwiritsa ntchito zotulutsa zamagetsi (zonse).Zida zimachotsedwa ku workpiece ndi mndandanda wazomwe zimatuluka mofulumira pakati pa maelekitirodi awiri, olekanitsidwa ndi dielectric fluid ndi kutengera mphamvu yamagetsi.Imodzi mwa ma elekitirodi amatchedwa electrode chida, kapena kungoti "chida" kapena "electrode," pamene ena amatchedwa workpiece electrode, kapena "workpiece". |

| Makina amitundu yambiri | Mtundu wa makina omangira omwe amagwiritsidwa ntchito popanga misa.Amaonedwa kuti ndiwothandiza kwambiri powonjezera zokolola pogwiritsa ntchito makina.Itha kudula bwino zinthu kukhala tizidutswa tating'ono pomwe ikugwiritsa ntchito zida zosiyanasiyana.Makina ambiri opota amakhala ndi zopota zingapo pa ng'oma yomwe imazungulira mopingasa kapena yopingasa.Ng'omayi imakhala ndi mutu wobowola womwe umakhala ndi zopota zingapo zomwe zimayikidwa pama bere a mpira ndikuyendetsedwa ndi magiya.Pali mitundu iwiri ya zomata za mitu yobowola iyi, yokhazikika kapena yosinthika, kutengera ngati mtunda wapakati wa spindle yobowola uyenera kusiyanasiyana. |

| Mtengo EDM | Zomwe zimatchedwanso EDM kudula waya, waya woyaka EDM, kapena waya woyendayenda EDM, njirayi imagwiritsa ntchito kukokoloka kwa spark kumakina kapena kuchotsa zinthu kuchokera kuzinthu zilizonse zamagetsi, pogwiritsa ntchito ma electrode oyendayenda.Waya elekitirodi nthawi zambiri imakhala ndi mkuwa-kapena zinki- TACHIMATA mkuwa chuma.Waya EDM imalola pafupi ndi ngodya za 90-degree ndipo imagwiritsa ntchito mphamvu zochepa kwambiri pazinthuzo.Popeza waya amakokoloka pochita izi, makina a EDM a waya amadyetsa waya watsopano kuchokera ku spool pamene akudula waya wogwiritsidwa ntchito ndikuusiya mu bin kuti abwezeretsenso. |

| Sinker EDM | Zomwe zimatchedwanso mtundu wa EDM kapena voliyumu EDM, EDM yozama imakhala ndi electrode ndi workpiece yomizidwa mumafuta kapena madzi ena a dielectric.Electrode ndi workpiece zimagwirizanitsidwa ndi magetsi oyenera, omwe amapanga mphamvu zamagetsi pakati pa magawo awiriwa.Pamene electrode ikuyandikira chogwirira ntchito, kuwonongeka kwa dielectric kumachitika mumadzimadzi ndikupanga njira ya plasma ndikudumpha pang'ono.Kupanga kufa ndi nkhungu nthawi zambiri zimapangidwa ndi sinker EDM.Zida zina, monga zida zofewa za ferrite ndi zida zamaginito zokhala ndi epoxy sizigwirizana ndi siker EDM chifukwa sizimayendera magetsi.[6] |

| Wodula jeti wamadzi | Imadziwikanso kuti "waterjet", ndi chida chomwe chimatha kudula zitsulo kapena zinthu zina (monga granite) pogwiritsa ntchito jet yamadzi pa liwiro lapamwamba komanso kuthamanga, kapena kusakaniza madzi ndi zinthu zowononga, monga mchenga.Nthawi zambiri amagwiritsidwa ntchito popanga kapena kupanga zida zamakina ndi zida zina.Waterjet ndi njira yomwe imakonda kwambiri pamene zida zomwe zimadulidwa zimakhudzidwa ndi kutentha kwakukulu kopangidwa ndi njira zina.Yapeza ntchito m'mafakitale osiyanasiyana kuchokera kumigodi kupita kumlengalenga komwe imagwiritsidwa ntchito ngati kudula, kuumba, kusema, ndi kukonzanso. |

CNC kubowola

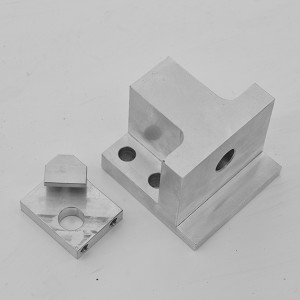

magawo

CNC makina

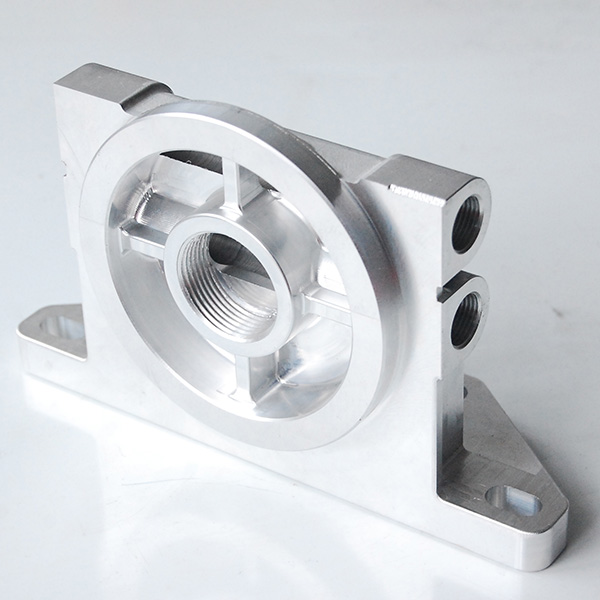

zigawo za aluminiyamu

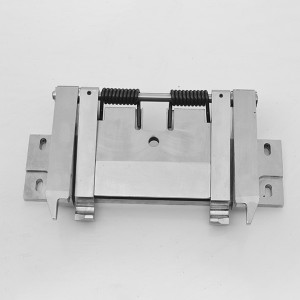

CNC makina

mbali zopindika

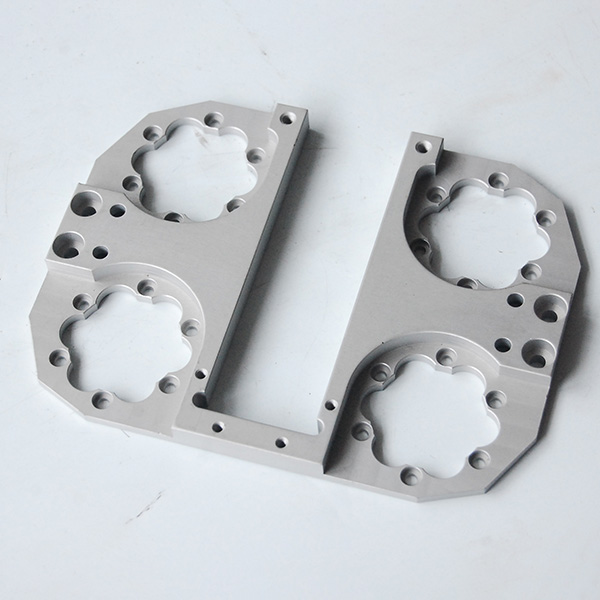

CNC Machining magawo

ndi anodizing

Kulondola kwambiri

magawo a cnc

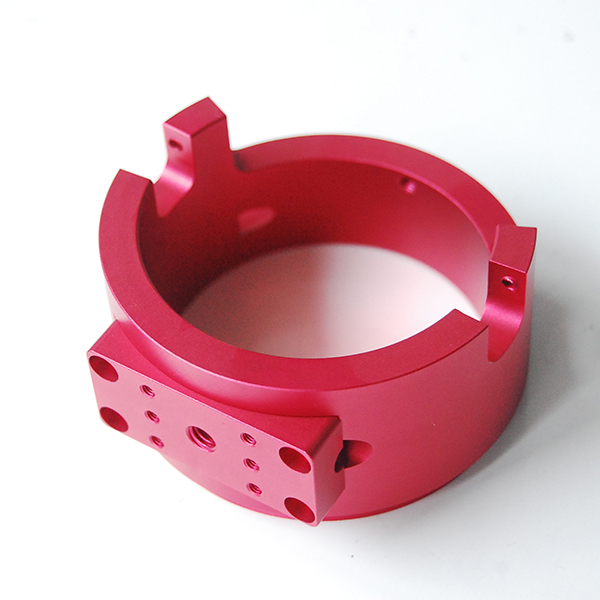

Kuponyedwa kolondola kwa aluminiyumu

ndi makina ndi anodized

Aluminiyamu ya Precision cast

ndi makina

Chitsulo cnc

makina opanga zigawo